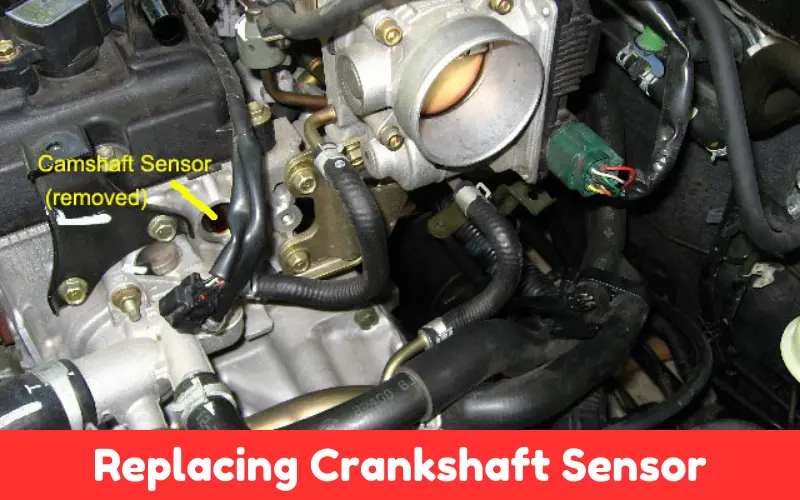

Crankshaft sensor replacement is vital to restore your vehicle’s operational reliability. After replacing the crankshaft sensor, some steps must be taken to integrate it properly into the system and avoid obstacles.

This guide will walk you through the crucial post replacement actions like confirm installation, start relearning procedure, and follow the test driving.

Replacing crankshaft sensor ensures that your vehicle stays in the best condition and will not create problems further. Let’s move on to what to do after replacing crankshaft sensor.

Article Summary

What Causes A Crankshaft Sensor To Go Bad?

A crankshaft sensor can fail due to many causes. In the long run this failure can affect the performance and reliability of your vehicle.

One of these reasons is aging parts as in high mileage cars can be particularly significant.

Besides, long term wear and tear on sensors are subject to high acceleration over their lives and temperature extremes, such as needing to jump into a cold vehicle when excitation is required.

Exposure to these temperature ranges and vibration from the engine can wear out sensor components, causing a decrease in reliability and eventual failure. Oil leaks can also harm sensors, as oil may enter contacts and wiring, leading to short circuits or corrosion.

Complicated matters in this way result from wear and tear on a sensor’s parts and how oil performs in largely unknown situations: incorrect wiring or poor connections, electrical problems consisting of signals being interrupted by the sensor.

Also, mechanical damage from accidents or improper handling during repairs might cause complete sensor failure. Contaminants like dirt and debris, if they accumulate around the sensor, can similarly affect its performance.

Timely addressing these problems and regular maintenance can help prevent early crankshaft sensor failure and ensure that your engine runs smoothly and efficiently.

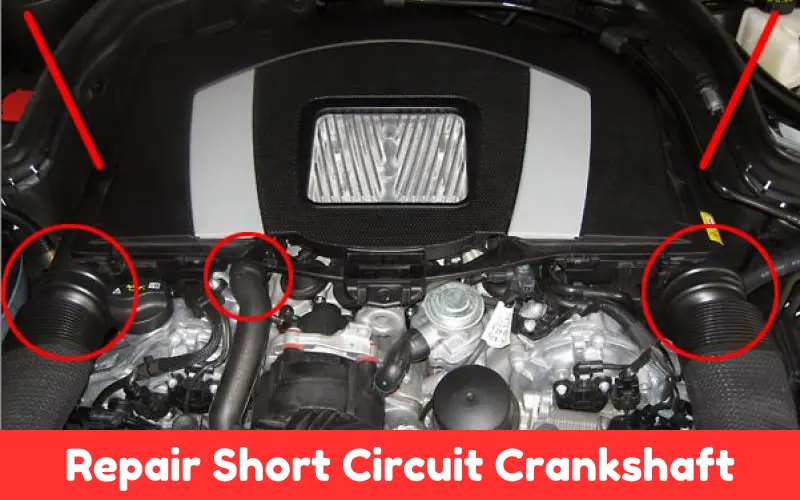

How To Repair Short Circuit Crankshaft Sensor Position

Repairing a short circuit in a crankshaft sensor requires a step by step way of determining and coping with the issue. The following is a step by step guide:

Safety First

Disconnect the Battery: Before starting, disconnect the car battery so as not to cause any electrical accidents.

Identify the Problem

Check Error Codes: Use an OBD-II scanner to read error codes set by the Engine Control Module (ECM). This can determine whether the Crankshaft Sensor Position is faulty.

Visual Inspection: Observe the crankshaft sensor and any connecting wiring for visible signs of damage, such as frayed wires, corrosion, or oil contamination.

Test the Crankshaft Sensor and Wiring

Multimeter Test: Use a multimeter to check the sensor’s resistance and continuity. Compare readings with the manufacturer’s specifications.

Check Wiring: Utilize the multimeter to verify that the wiring harness is functioning properly. Look for continuity from the ECM to all sensors and actuators on this circuit and any shorts to the ground.

Repair the Wiring

Replace Damaged Wires: Any damaged or frayed wires should be obliterated and replaced with new cables of suitable gage. Solder and heat shrink tubing must ensure good electrical connection and protection from the elements for years.

Fix Connectors: Clean and check that each electrical connector is firmly in place. If a connector is corroded, clean it or replace it to ensure good electrical contact.

Reinstall and Test

Reconnect Sensor: Reinstall the sensor and reconnect all wiring. Make sure all connections are tight.

Reconnect Battery: Reconnect the car battery.

Troubleshooting: Start the vehicle and check engine for regular operation. Make sure that the OBD-II scanner does not set fault codes.

Final Inspection

Monitor Performance: Run the vehicle for a road test, monitoring its performance. Ensure no warning lights are on and the engine runs smoothly.

What To Do After Replacing Crankshaft Sensor?

Replacing crankshaft sensor is a significant repair that can restore your vehicle’s performance and smooth engine operation.

Yet just changing the sensor will not fix everything: follow these instructions for what to do after replacing your crankshaft sensor.

Make Sure the Installation is OK

You have yet to finish the job since the new crankshaft sensor is in place, so go over everything quickly for a final check: make sure that.

- The crankshaft sensor is seated and secured correctly.

- Your electrical connections are tight and free of corrosion.

- Any mounting bolts meet torque specifications issued by the manufacturer.

Clear Diagnostic Trouble Codes (DTCs)

After replacing the crankshaft sensor, it is essential to erase any diagnostic trouble codes stored in the vehicle’s computer. Use an OBD-II scanner to:

- Read any codes still there

- Clear these codes so that the check engine light resets.

- This is very important, as no new issues must be misdiagnosed.

Relearn the Process

Many modern vehicles require a sensor relearn procedure after replacing the crankshaft sensor position. This allows the engine control module (ECM) to recalibrate the sensor for peak performance.

By studying your car’s service manual, you can find out the exact steps, which generally require:

- Starting the engine and letting it warm up to average operating temperature

- Following specific driving patterns or idling

Test Drive the Car

Take your car out for a test drive to ensure everything works. Pay attention to:

- Smooth engine start up.

- Idling is consistent, with no stumbling or stalling involved

- No strange noises or vibrations anywhere

By taking it on a test drive, you can identify any remaining problems needing attention

Keep an Eye On the Engine Performance

After the test drive, be sure to check the performance of your engine for a few days to come. Watch for any signs of:

- Lack of power and acceleration.

- Engine misfires.

- Fuel Efficiency Issues

If you see smoke funking all over, your car smells like rotten eggs, and you might have lost power while driving on the highway, your O2 sensor has crapped out on you.

Check for Leaks in the Oil System

Once you have replaced the sensor and cleared the engine fault code, checking for oil leaks is a good idea. Because the crankshaft sensor is often located near oil seals or the oil pan, look at both areas carefully to see if anything leaks.

Any leak needs prompt repair to avoid future engine problems later on. In extreme cases, oil might even leak onto the sensor itself from a crack in the block casting, so this warning should not be ignored.

Schedule a Follow Up Check

For outside checks or if your car still has problems, plan to take it in and have a pro mechanic check them out.

Regular Maintenance

Be sure to schedule routine maintenance on your car. Regular inspections and servicing should be done at the proper intervals to catch problems before they get out of hand.

Does A Replacing Crankshaft Sensor Have to Be Programmed?

Yes, a new crankshaft position sensor typically requires learning or programming by the vehicle’s engine control module (ECM). This allows the ECM to calibrate O2 sensor and other sensors for better engine performance.

Relearning normally involves starting the engine and following a particular driving pattern. This varies by vehicle make and model; refer to your vehicle’s service manual for complete instructions.

Not doing programming can lead to problems such as poor engine performance, stalling, or code complaints. In case of doubt, have the sensor installed and programmed professionally to ensure things are done right.

FAQs On What To Do After Replacing Crankshaft Sensor

What Are the Symptoms of A Failing Crankshaft Sensor?

A failing crankshaft sensor may cause a variety of symptoms. These include difficulty starting the engine, intermittent stalling (tackling), misfires (immature firing), rough running or poor acceleration, reduced fuel efficiency, and an illuminated check engine light.

Can I Drive with A Bad Crankshaft Sensor?

Although you may be able to drive with a faulty crankshaft sensor, it is not recommended. A bad sensor can cause engine performance issues, make stalling likelier, and lead to further damage.

How Long Does It Take To Replace A Crankshaft Sensor?

Depending on the vehicle’s make and model of the vehicle, fixing crankshaft sensor takes about 1 to 2 hours. The process involves locating the sensor, removing the old one, installing a new sensor, and possibly performing a relearn procedure.

What Causes A Crankshaft Sensor To Fail?

Wear and tear, exposure to high temperatures, fluid leakage, electrical system failure, mechanical damage, dirt, or foreign matter may be responsible. Cleaning and maintaining your car correctly can extend the service life of a sensor.

Conclusion

Despite the ways that installation of a crankshaft position sensor can boost your car’s performance, maintenance and service are the things that truly determine whether long term operations meet with reliability and efficiency.

Checking your breath, ridding yourself of DTCs, performing a relearn procedure, and observing how the engine works can all help ensure you arrive home safely.