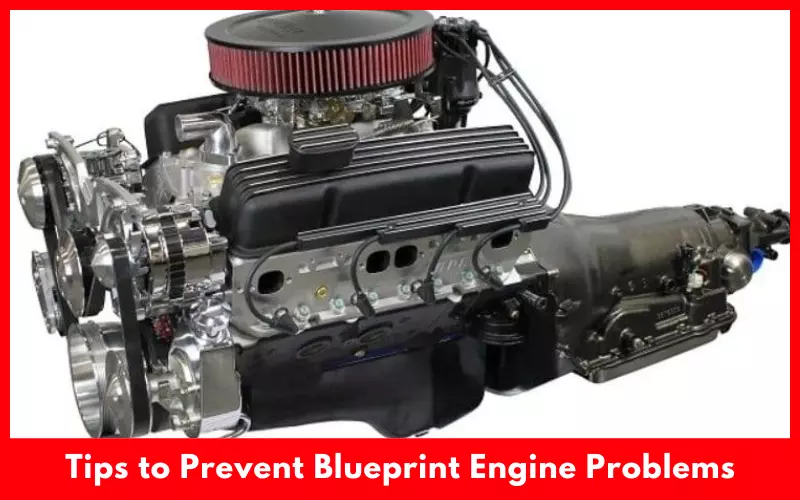

Blueprint engine is quite unbeatable for its affordable price tag, impressive warranty, more powerful motor and complete packaging. Still, few owners suffer from blueprint engine problems that need attention and fix before becoming worse.

Some common blueprint engine problems are durability issues, bearing failure, overheating, leaking gaskets and improper tuning. Many users are also unhappy with its warranty policy. However, you can avoid most of those issues and enjoy satisfying customer service following the blueprint’s instructions.

Article Summary

8 Common Blueprint Engine Problems

Below are some common blueprint engine problems that you may experience:

1. Durability

Durability is one of the main concerns for blueprint engines. You may have a satisfied three-year service from the blueprinted engine. After that, you’ll need to replace some components of the engine depending on the level of stress the motor face.

Some users complain that the engine’s motors are assembled around the used block and have thin walls. The engine’s rocker arm may also break down over time.

2. Bearing Failure

All the blueprint engines and their valve cover and oil pan come pre-lubricated and dyno tested. Still, the engine requires extra preventative maintenance like pre-lubrication before initial startup. If you don’t apply pre-lubrication process is performed properly, you will get broken or bad bearing in the engine as it comes dry and drains.

The engine’s moving parts will also cause excess friction and rubbing without oil which can break the bearings apart. To avoid the problem, fill the oil pan and oil filter to recommend capacity using the blueprint’s breaking oil. Make sure the ignition source doesn’t have the power to avoid causing fire prematurely in the cylinders.

Then remove the spark plug and run the engine for 20 seconds to crank the engine with a starter. Wait for 20 seconds in between cranks to let the starter cool the engine.

If you can’t see oil pressure on the electronic gauge, use a mechanical gauge to ensure oil pressure and support the pre-lube friction surfaces. Finally, install the spark plugs and start the initial setup.

3. Engine Overheating Problem

Overheating is another common problem of blueprint engines that can damage the engine completely. Driving with an overheated engine can cause immense repercussions even if it is only for a few miles. Your blueprint engine can overheat before 500 miles break in.

If the engine undergoes extreme combustion, it can also melt or block the engine’s block. However, you can avoid this issue by installing a thermostat and bypass purge valve. These equipment will measure the temperature level and release the excess heat. Also, increase the mechanical engine timing to 24° to 34° during performing break-in to avoid making the engine overheat.

4. Leaking Gaskets

The head gasket of an engine plays a crucial role to seal the engine’s combustion chamber. Hence the car can build the perfect compression that is required to maintain engine power. It also helps prevent the oil or coolant from leaking and prevent the engine from overheating and catching fire.

A bad head gasket of a blueprinted engine causes the engine to lose power and forces the engine to knocking, run roughly at idle and stalling.

Many blueprint engine owner experience these issues due to leaking gaskets. It causes due to insufficient torque or loosening during heat cycles. The symptoms include coolant puddles under the vehicle, the low coolant level in the reservoir, a strong smell, and white smoke coming from the exhaust.

To avoid this problem, re-torque the manifold bolts after performing a heat cycle to ensure a secure seal. If you are using an aftermarket header, consult with the manufacturer to get the proper gasket. Secure the intake, water pump bolts ad front accessory to prevent them from loosening during the heat cycle.

5. Leaking Intake Manifold

The intake manifold help distribute the air coming into the engine evenly to the whole cylinders. It also helps cool down the cylinders and prevent the engine from overheating. However excess vibration from an inaccurately installed flexplate or harmonic balancer can cause a leak in the intake manifold. Many blueprint engine owners experience this particular issue.

A leaky intake manifold sucks outside air in and causes decreased acceleration, engine misfire, and poor fuel economy. It can also make the engine overheat. However, you can fix this problem by applying one bottle K-Seal as it seals the intake manifold for a permanent repair.

6. Improper Tune or no Tune

It’s crucial to set the timing to run the blueprint engine. If you don’t set the timing according to the recommendation, it can void the warranty and cause engine failure. An incorrect tune-up can also cause poor engine power, detonation, and overheating. The longevity of pulleys, pistons, camshafts, rods, timing belts, crankshafts, and valves also depends on the tune-up.

Many blueprint users experience improper tuning or no tune due to tuning up wrongly. The first-time tuning up of the blueprinted engine is vital for maintaining its longevity. To make the process accurate, follow the procedure mentioned in the user manual of your blueprint engine.

7. Engine Fails

In severe cases, your blueprint engine may fail. Among lots of reasons, improper break-in and not using oil with zinc additive are most common. Blueprint recommends using zinc additives, particularly for an engine with flappet cams.

So if your blueprint engine has rolling cams, it won’t require zinc additives. Instead, you should keep using the breaking oil to avoid engine failure.

In terms of the break-in, it’s a process to wear in the cam loves around a 20 minutes cycle so the zinc oil can break in properly in the cam surfaces and mechanical lifters.

8. Warranty

Blueprint offers 50,000 miles or 30 months warranty on their crate engine. However, you must follow their instructions properly during the break-in period to approve any claim. Most of the factory defects occur within the break-in period. Many blueprint engine owners complain that their claims have been disapproved.

Avoiding the break-in procedure is the main reason for it. Otherwise, blueprint offer satisfied customer service and ships the replacement parts quickly if required. They also provide a one-year warranty on the replacement parts.

Maintenance Tips To Prevent Blueprint Engine Problems

The Blueprint engine is a perfect choice for daily driving, thanks to its reliable horsepower. It also comes from a solid and reputable company maintaining strict standards. So if you can avoid or fix blueprint engine problems, it’ll be your top-notch performer even at an affordable price.

To avoid these potential issues, first, inspect your crate engine when receiving it and make sure it has all the parts required for installation. Then, follow all instructions properly during installation as most blueprint engine problems occur due to neglecting the right installation process. Be careful during the break-in periods and tuning up the engine.

The other maintenance tips you should follow are:

- Don’t use synthetic engine oil during or after break-in periods as it isn’t essential for the blueprint engine.

- Check the fluid level frequently during the break-in period.

- Recheck the external bolts of the intake manifold, front accessories, and exhaust as these can come loose during heat cycles.

- Replace the oil filter and oil every 3,000 miles or 3 to 4 months particularly if you don’t drive the car regularly.

- If you drive the car in a dusty or heavy environment, change the oil and oil filter more frequently.

- If you live in colder regions, use lower-viscosity oil to get better flow characteristics.

FAQs

Are BluePrint Engines Good?

Blueprint engines offer high-temperature viscosity and ensure effective wear control. It also protects bearings at initial start-up and high speed. Blueprint engines also don’t require any additional additives while coming at an affordable price, making them a decent choice for any compatible vehicle.

How Much Does It Cost To Fix Blueprint Engine?

The cost of a blueprint engine varies depending on the model, accessory drive pulley system, and whether the system is black or polished aluminum. The GM 530 HP crate engines cost around $8500 to $10,000.

Is it Expensive To rebuild or Buy A Blueprint Engine?

Though the blueprint crate engine comes at an affordable price, remanufactured engines are still cheaper. Even if you want a stock replacement motor, the remanufactured engine will be preferable. But if you have enough budget and need more power, a crate engine will be a better choice.

Final Words

Most of the crate engines come incomplete. But blueprint premium crate engines come complete with all the essentials. These engines are dyno tested, balanced and made of forged or cast components.

Even you can avoid most of the blueprint engine problems by following the manufacturer’s instructions and taking proper care of the engine to enjoy the most out of it. Still, if you face any problems, contact BluePrint Engines customer service.

If these engines are balanced, why isn’t the flex plate included especially the 383 I’m considering???

I have a blueprint 383,and I’m having an issue with a sloppy timing chain,seriel no.bp38318ctcid 369168, I’ve taken pictures of the chain….it moves almost a1/2 inch ,

Before investing money on machines, I always check reviews and problems. Blueprint engine problems are not so critical I think.