Faulty fuel rail pressure sensors directly impact on car engine power, speed and fuel efficiency. So if your car displays P0194 error code related to the fuel pressure sensor, you must inspect and repair the faulty sensor.

If you know how to bypass a fuel rail pressure sensor that would help to clear the code in an emergency. You can continue driving the car without any consequences.

In this case, you have to disconnect the sensor, check the wiring, bypass the sensor using a bypass pipe or LED test light and test drive to verify.

Article Summary

How To Bypass A Fuel Rail Pressure Sensor?

If your car displays an error code related to fuel rail pressure sensor, you can bypass it to clean the trouble code. However, bypassing the fuel rail pressure sensor is a bit tiresome process as it needs to deal with car fuel system.

So, if you have technical skills and some patience, follow these steps to bypass fuel rail pressure sensor on your vehicle.

1. Locate Fuel Rail Pressure Sensor

The fuel rail pressure sensor is usually located within the engine compartment mounted on fuel rail. The fuel rail is a metal pipe that supplies fuel to injectors. Check your car owner’s manual to locate the exact position of the sensor.

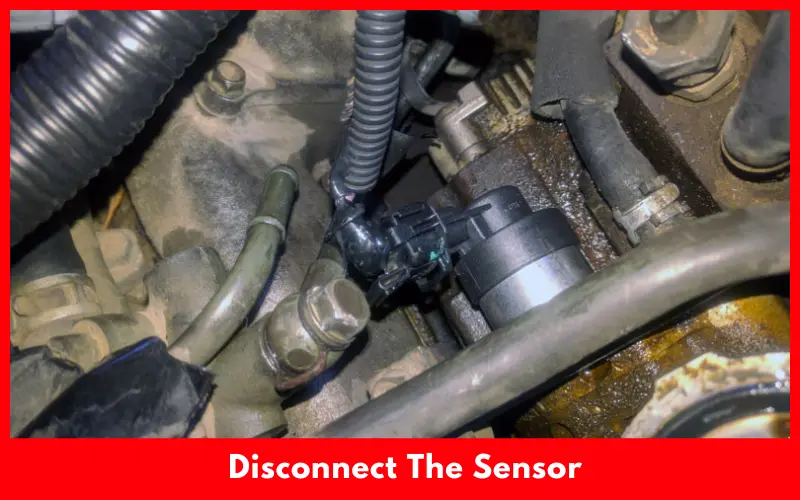

2. Disconnect The Sensor

Before disconnecting sensor, detach the power source to prevent electrical mishaps. In this case, remove battery’s negative terminal to deactivate all electrical components. Then release pressure from fuel system to prevent fuel from spraying out and disconnect the wiring harness.

Finally, disconnect fuel sensor carefully from the wiring harness to prevent fuel from spilling out.

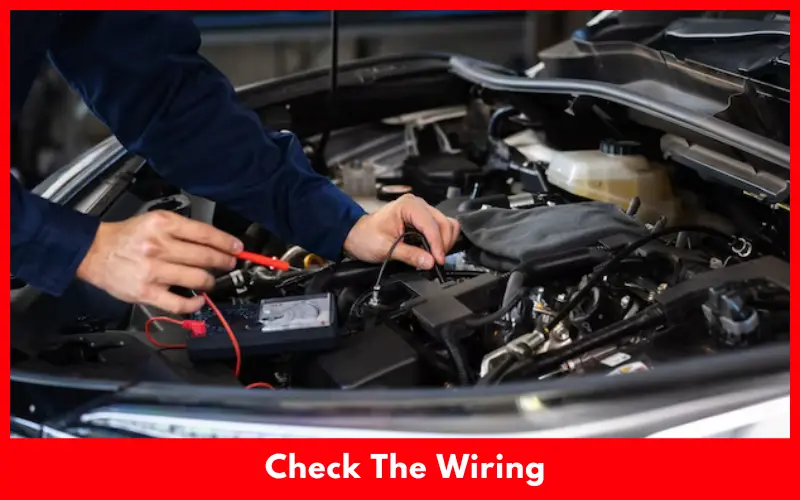

3. Check The Wiring

Check the wiring that is connected to the fuel sensor. Make sure the wiring isn’t damaged, worn out, or fried as it can interfere with bypassing the sensor.

4. Bypass Fuel Rail Pressure

To bypass fuel rail pressure sensor, you have to lead the resistor within circuit. In this case, connect LED test light on one end to the ground wire and the other end to signal wire. This setup aims to fool ECUs and force them to believe that the fuel pressure sensor is connected and working properly.

You can also install a bypass pipe to bypass the sensor. Make sure the pipe is same diameter and has same thread pitch as the sensor to avoid causing leaks. Then re-connect the wiring harness to bypass the pipe.

5. Check The Result

Once you have bypassed the sensor, turn on your car and check its performance. If your car performs smoothly and the error code doesn’t come back, you have successfully bypassed the sensor.

Challenges of Bypassing Fuel Rail Pressure Sensors

It can be quite challenging to bypass a fuel rail pressure sensor as it has plenty of variables. When bypassing a fuel rail pressure sensor, you must read 2.6 volts of atmospheric pressure on the vent tank. Then you’ll need to read 1.3 volts deep vacuum while performing an evap running loss test on PCM.

The next complex step is to change the 1.3-volt deep vacuum to a 2.6-volt atmosphere within the allotted time while performing evap vent test. Then you’ll need to lower or raise the atmosphere rating based on temperature for the vapor generation test. If you fail any of these tests, it’ll set a new code and activate check engine light.

You may also need to install a fixed resistor to read 2.6 volts and remove the sensor code. Hence many experienced mechanic finds it easier to replace the rail pressure sensor than make PCM fool with these values.

Common Symptoms of Faulty Fuel Rail Pressure Sensor

Fuel rail pressure sensor is a part of the fuel injection system and it monitors fuel pressure to ensure that the engine receives required fuel.

It usually lasts as same as the vehicle it comes with. However, it can fail earlier and show these symptoms:

Check Engine Light

PCM tests fuel rail pressure sensor regularly using the rationality test method and a fuel sensor ensures proper fuel supply so the engine gets sufficient gasoline. But if the fuel pressure sensor gets damaged, engine won’t get the required gasoline can cause hard starts, loss of power, or no starts. When PCM detects out-of-range input from sensor, it activates the check engine light.

Poor Engine Performance

If your car engine generates less power than usual, it can be result of a bad fuel rail pressure sensor. ECM uses the feedback input of fuel pressure sensor to determine the amount of pressure in the rail.

When the sensor gets damaged, ECM won’t be able to detect right pressure in engine. Hence engine also won’t get enough fuel to perform properly under high load. It can cause engine to run lean and deliver poor performance.

Bad Fuel Economy

If engine receives more fuel than required due to a faulty fuel rail pressure sensor, it’ll run rich. Hence you’ll experience low fuel economy.

Engine Runs Rough

PCM can let the engine add too little or too much fuel to the mixture due to getting wrong information from a faulty fuel pressure sensor. Hence engine can run rich due to improper air-fuel mixture and cause run rough. The engine can also misfire and make knocking noise due to the same reason.

How To Test A Fuel Rail Pressure Sensor With A Multimeter?

To test the fuel rail pressure sensor using a multimeter, locate the sensor first which is usually placed on fuel injector rail. Then disconnect electrical connector from the sensor and set multimeter to ohms setting.

Set Multimeter

Place multimeter probes on the terminals of the sensor and read volts. Depending on engine speed, you may read voltage around 1.32 volts to 3.77 volts. But if you don’t notice any continuity, you have to replace the faulty sensor.

Use A Scanner

You can also check the fuel rail pressure sensor condition even without using a multimeter. In this case, you have to use a scanner that will display live data. So disconnect the pressure sensor and read voltage using a scanner. You should read a voltage of around 4.99 volts. After that, connect a jumper between the signal and signal return wires.

Examine Voltage

The sensor’s voltage should drop to zero. If you notice a voltage change as explained, the fuel rail pressure sensor gets damaged. If not, the wiring between the PCM and the sensor gets damaged. The quickest way to check fuel rail sensor is to read it when the engine running at various RPMs. If readings change abnormally, the sensor possibly gets damaged.

FAQs

Can You Drive With A Bad Fuel Pressure Sensor?

You can drive with a bad fuel rail pressure sensor particularly if it doesn’t fail. However driving with a faulty fuel pressure sensor can cause the engine to run rich or lean, low engine power, or even engine damage. Though you can continue driving with a bad fuel pressure sensor for a short time, you should replace the worn-out or damaged sensor before it gets worse.

How To Reset The Fuel Rail Pressure Sensor?

You can easily reset the fuel rail pressure sensor to see if it disappears from the error code. To do this, disconnect the battery and re-connect it after 30 seconds. It will fix error code. Then turn your vehicle on and let it idle for around 5 minutes so the ECM can gather required information. Don’t accelerate the engine when idling. Finally, drive your car at around 20km/h to allow the ECM to gather information again.

Can You Run A Car Without A Fuel Fail Pressure Sensor?

You shouldn’t run your vehicle without a fuel rail pressure sensor. If you unplug the fuel pressure sensor, the pump will run at a set speed and cause engine to run at low power and throttle. It can increase emissions and reduce fuel economy.

Final Words

Hope you understand how to bypass a fuel rail pressure sensor and should be able to clear the trouble code by making the ECU fool. However, don’t overlook the challenges of bypassing fuel rail pressure. This is because doing anything wrong can trigger more error codes than now. So if you aren’t confident enough, bring the car to the nearest mechanic shop and replace the faulty fuel rail pressure sensor before it damages the whole engine.